This post contains affiliate links.

Understanding the critical components of your home’s water system can often seem like plumbing wizardry. You might be surprised to learn that the magic behind consistent water pressure lies in a standard fixture – the pressure tank. Spanning across a variety of models and advancements, pressure tank technology plays a pivotal role in not just maintaining pressure but ensuring the longevity of your water system. Let’s dive into pressure tanks benefits, unravel the pressure tank working principle, and explore how today’s pressure tank technology has evolved to meet modern demands.

Key Takeaways

- Discover the vital pressure tanks benefits to your home water system.

- Uncover the pressure tanks explained: how these tanks work to deliver water on demand.

- Learn about the pressure tank working principle that avoids unnecessary pump wear and tear.

- Gain insights into the advancements in pressure tank technology for improved system efficiency.

- Understand the importance of having the right pressure tank to ensure consistent water supply and pressure.

- Explore how modern pressure tanks contribute to energy savings and a reduction in system maintenance needs.

- Realize the full scope of pressure tank applications in residential water systems.

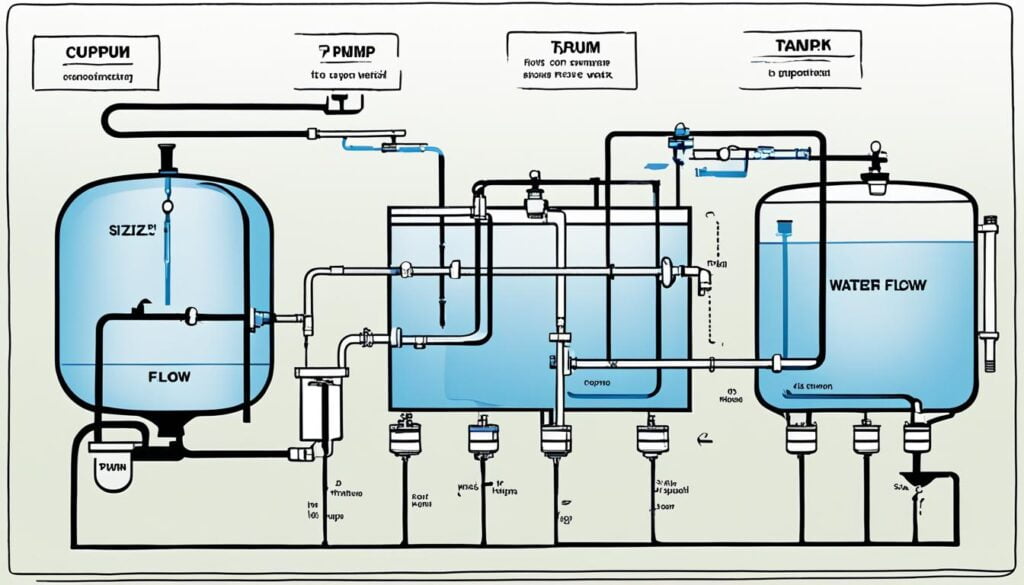

The Fundamental Roles of Pressure Tanks in Private Water Systems

When you’re considering the integration of a pressure tank into your private water system, understanding its core roles is crucial. The seamless operation of modern households often relies on the consistent performance of these components. Here’s how pressure tanks enhance your water system’s efficiency and relieve stress on your pump’s operation.

Water Storage and Delivery Under Pressure

One of the crucial pressure tank functions is storing water and delivering it under pressure as needed. This eliminates the necessity for the pump to run continuously, ensuring a steady water flow when you turn on your faucets. Especially critical in situations where direct water access is hindered, pressure tanks maintain a balanced distribution system, providing pressure tank advantages such as uninterrupted service and reduced energy consumption.

Preservation of Pump Longevity Through Cyclical Reduction

By reducing the start-stop cycles of the pump, pressure tanks contribute significantly to its longevity. They act as a buffer, absorbing water surges and alleviating the demand on the system. This cyclical reduction is vital in preserving the mechanical integrity of the pump, which can otherwise degrade from the wear and tear associated with frequent activation.

Ensuring Water Availability During Peak Demands

During times of high demand within your household, you might wonder, what are pressure tanks good for? The answer lies in their ability to provide an immediate response to these peak periods. With a reserve supply of pressurized water, pressure tanks prevent any compromise in water accessibility, proving their indispensability in every efficiently managed water system.

For a clear understanding of how these tanks are beneficial for various household needs, consider this comparison:

| Without Pressure Tank | With Pressure Tank |

|---|---|

| Frequent pump activation | Reduced start-stop cycles |

| Uneven water pressure | Consistent water pressure |

| Pump wears out quicker | Extended pump lifespan |

| Potential water shortages during peak use | Continuous availability during high demands |

These vital roles of pressure tanks assure that your private water system remains efficient, reliable, and above all, capable of meeting the demands of your daily water usage.

Understanding How Pressure Tanks Function

Gaining insight into the inner workings of pressure tanks is key to appreciating their role in your water system. Two fundamental principles drive their operation: the incompressibility of water and the compressibility of air.

The Principles of Water and Air Compression in Pressure Tanks

At the heart of pressure tank operation is the concept that water remains incompressible under pressure, while air can be easily compressed. This dichotomy enables pressure tanks to store water under pressure. Inside the tank, as water level rises, the air above gets compacted, increasing the pressure until it reaches a pre-determined point that is optimal for your usage.

Regular Operation Cycle: Pressure Build-up and Release

Understanding how pressure tanks work unveils a cyclic dance of pressure build-up and release. The system begins with the pump channeling water into the tank, leading to compressed air and rising pressure. This process halts once the maximum pressure setting is reached. Thereafter, as water exits the tank for your household needs, the diminished volume naturally lowers the pressure. This drop triggers the pump to start again once the minimum pressure threshold is crossed, thus repeating the pressure cycle and ensuring a consistent water supply.

At this juncture, let’s visualize the cycle with a table that outlines key operational stages:

| Operation Stage | Activity | Pressure Status | System Response |

|---|---|---|---|

| 1. Fill-up | Water enters; Air compresses | Increasing | Pump on |

| 2. Cut-off | Max pressure reached | High preset limit | Pump off |

| 3. Consumption | Water exits; Air expands | Decreasing | – |

| 4. Re-activation | Pressure drops to minimum | Low preset limit | Pump on |

The pressure within the tank is meticulously calibrated to exceed the demand of the most pressure-intensive appliances, ensuring that every element of your water system operates smoothly. In essence, the function of pressure tanks revolves around a delicate balance between the mechanical input from your pump and the natural physics of air and water.

What Are Pressure Tanks Good for . How Do They Work?

When examining what pressure tanks are good for, it’s clear they serve as an indispensable part of a well-regulated water supply system. With the ability to offer instant access to pressurized water, they are key to both residential and commercial settings, ensuring that your water needs are met with efficiency and reliability. But how do pressure tanks work to provide such benefits? By storing water under a pre-set pressure, these tanks enable the delivery of water on demand while sparing the pump from overuse, thus contributing significantly to the conservation of energy and extending the lifespan of the pump system.

Due to their design, pressure tanks can function without the need for manual intervention, automatically responding to the drop in water pressure as water is used and then reactivating the pump only when necessary. This seamless operation not only aids in energy preservation but also ensures that your home or business has uninterrupted access to water at the desired pressure. The convenience offered by pressure tanks both in terms of energy savings and dependable water access is what makes them such a valuable component of any well water system.

Pressure tanks’ applications are vast, and they are utilized in various scenarios beyond just well water systems. They play crucial roles in agricultural irrigation systems, fire protection operations, and in industrial settings where hydraulic processes are vital. Their versatility is reflected in their different uses—whether it’s maintaining steady water pressure in a high-rise building or regulating supply in a heating system, pressure tanks prove to be versatile in application.

Understanding the pressure tanks uses and how they fit into your specific water system can lead to more informed decisions when it comes to selection and maintenance. Whether you’re outfitting a new building or upgrading an existing system, recognizing the critical role and applications of pressure tanks ensures that your investments in these systems are well-placed and productive.

- Automated water delivery for consistent pressure with minimal pump wear.

- Increased energy efficiency with reduced pump operation frequency.

- Designed for integration with pressure switches and well systems.

- Essential for uninterrupted water supply across residential and commercial spaces.

- Adaptive for use in irrigation, fire protection, and industrial hydraulic systems.

In conclusion, by understanding pressure tanks uses and the mechanisms by which they work, you can better appreciate their value in a well-functioning water system. These tanks offer more than just convenience; they are a testament to the engineering that helps conserve resources while reliably meeting our daily water needs.

The Transition from Galvanized Steel Tanks to Modern Bladder and Diaphragm Tanks

As we explore the advances in pressure tank technology, we witness a significant shift from the historically used galvanized steel tanks to the more efficient bladder and diaphragm tanks. This progression has been driven by the pursuit of enhancing pressure tank benefits and incorporating essential pressure tank upgrades to meet modern demands.

Drawbacks of Old-Style Galvanized Steel Tanks

Traditional galvanized steel tanks have served their purpose in the past but come with a critical downside – the inevitable mixing of water and air. This direct contact leads to the absorption of air into the water, causing waterlogged conditions which necessitate recurrent air charging to maintain functionality. The associated frequent cycling of pumps implies higher energy consumption and increases the likelihood of wear and tear, consequently shortening the equipment’s lifespan.

Advantages of Using Bladder and Diaphragm Pressure Tanks

The emergence of bladder and diaphragm technology in pressure tanks has revolutionized the system’s efficiency. With a design that segregates air from water, these tanks possess an inner membrane – the bladder or diaphragm – that dilates and contracts based on water usage, thereby stabilizing pressure. This remarkable feature eliminates the need for constant air recharge and minimizes the operational frequency of the pump, leading to a notable decrease in energy usage and maintenance.

- Elimination of water-logging issues

- Decreased need for pump cycles

- Maintenance reduction leading to cost savings

- Longer lifespan of water systems

The financial and functional advantages of upgrading to bladder or diaphragm pressure tanks are clear. Such improvements align with environmental considerations by reducing energy consumption and providing a reliable water delivery system that requires less intervention, ultimately translating to a sound investment for the future.

Understanding the progression in pressure tank technology is pivotal when considering system upgrades. Contemporary bladder and diaphragm tanks are defining the new standards in pressure tank benefits, offering not just improved performance but also an eco-friendlier and cost-effective solution for water systems.

Pressure Tank Technology: Types and Advancements

In the realm of pressure systems, the evolution of tank technology has been both robust and substantial, offering compelling pressure tank advantages across a variety of sectors. As you explore the modern landscape, a noticeable shift from conventional models to innovative designs is evident, driving efficiency and reliability to new heights.

From Air-over-Water to Diaphragm and Bladder Tanks

Initiating with the traditional air-over-water tanks, these have historically been the backbone of pressure tank applications. However, the inception of diaphragm and bladder tanks has redefined the benchmarks for pressure tank operation. These advanced tanks are ingeniously crafted to eliminate issues such as water logging and reduce the maintenance burden on system owners.

The diaphragm tanks, with their separate chambers for air and water, procure improved water pressure control and a discernible decrease in pump cycling. Similarly, bladder tanks, with their replaceable bladders, present a straightforward maintenance process—assuring a longer service life and cost-efficiency.

Contemporary Materials and Manufacturing Techniques

Today’s pressure tanks are built with cutting-edge materials including durable steel and corrosion-resistant stainless steel. Developers favor these materials for their ability to withstand considerable pressures and fluctuating temperatures—key factors ensuring the integrity of pressure systems.

| Pressure Tank Type | Material Benefits | Operational Advantages | Industry Applications |

|---|---|---|---|

| Diaphragm Tanks | Robust, less susceptibility to corrosion | High-pressure retention, reduces pump cycles | Domestic water systems, HVAC |

| Bladder Tanks | High flexibility, easy to replace | Low maintenance, consistent performance | Industrial processes, irrigation systems |

| Air-over-Water Tanks | Simple construction, cost-effective | Straightforward design, easy installation | Rural water systems, low-demand settings |

To further augment the structural sanctity and forestall any potential leakage, tanks may be enveloped in polymers or rubber coatings. Innovations in design and manufacturing empower these tanks to serve a broad spectrum of pressure tank applications, verifying their role as indispensable components within a multitude of industries.

Whether it’s the steadfast operation in a residential setup or the stringent demands of industrial environments, the modern pressure tank not only sustains but enhances overall system performance. In acknowledging these continuous advancements, you can appreciate how pressure tank technology shapes the efficiency and safety of pressure-related operations.

Sizing Your Pressure Tank: Best Practices Based on Pump Flow Rate

Ensuring your water system operates efficiently starts with selecting the correct size for your pressure tank. When it comes to pressure tank sizing, factors such as the flow rate of your pump are paramount to accommodate water usage patterns effectively. Let’s dive into the recommended sizing formula and understand why it is essential for the pressure tank function within your water system.

The Formula for Selecting the Right Tank Size

When you’re in the market for a new pressure tank, understanding the proper size for your system can seem daunting. However, a widely recognized formula can help simplify this process. For diaphragm or bladder tanks, aim for a capacity that is four times the pump’s flow rate. If your system uses a steel tank without a wafer, sizing it at ten times the flow rate is advisable. This guideline ensures that your pressure tank can handle the water demand effectively without overworking your pump, an insight that’s integral to pressure tanks explained for optimal system performance.

Special Considerations for Low-Yield Wells

If your water source is a low-yield well, paying attention to tank size becomes even more critical. A tank that’s too small could lead to frequent cycling of the pump, causing wear and compromising the entire system. However, larger tanks may be underutilized and inefficient. To strike the right balance, consulting with a seasoned pump supplier who understands the intricacies of pressure tank sizing and pressure tank function can save you from costly mistakes and ensure a steady, reliable water supply.

Pressure Tanks in Constant Pressure Water Systems

The integration of Variable Frequency Drive (VFD) has transformed constant pressure water systems, redefining the conventional pressure tank function. Unlike traditional setups, VFD-equipped systems finely adjust the pump’s operation to match water demand, thereby maintaining steady pressure and enhancing user experience. This smart technology presents numerous advantages for residential and industrial water supply, making it a sought-after solution for those seeking uninterrupted and consistent water delivery.

Role of Variable Frequency Drive (VFD) in Pressure Maintenance

At the heart of modern constant pressure systems lies the Variable Frequency Drive—a marvel of engineering that dynamically alters the speed of the pump’s motor. This constant adaptation minimizes pressure fluctuations despite varying water usage, leading to less wear on both the pump and the pressure tank. With VFD in action, you experience a sustained water pressure that closely resembles the service provided by municipal water systems.

How VFD-Driven Systems Alter Pressure Tank Requirements

In a traditional setting, large pressure tanks are necessary to cope with water demand surges. However, VFD technology diminishes this requirement significantly. Current systems may only need a small expansion tank to accommodate the pressurization, quite different from the traditional rules of thumb for tank sizing. Let’s look at a comparison:

| System Type | Pressure Tank Size | Energy Consumption | Water Pressure Stability |

|---|---|---|---|

| Traditional System | Large (20-80 gallons) | Higher | Variable |

| VFD System | Small (1-2 gallons) | Optimized | Consistent |

The table underscores how VFD-driven systems not only scale back on the size of the pressure tank but also optimize energy usage and provide a level of water pressure consistency not seen in older systems. This innovative approach has made constant pressure water systems a preferred choice for savvy homeowners and businesses looking to modernize their water supply infrastructure.

Materials and Design Approaches in Pressure Tank Manufacturing

When it comes to the manufacturing of pressure tanks, every detail matters—from the choice of pressure tank materials to the precision in pressure tank design. These elements are not just about aesthetics; they are crucial for the tank’s ability to perform safely and reliably during pressure tanks operation. A deep understanding of how these factors interplay is essential for both manufacturers and end-users.

Criteria for Material Selection and Longevity

One of the most important decisions in pressure tank fabrication is the selection of materials. Manufacturers look for materials that can withstand the rigours of both high pressure and variable temperatures. Metals like steel and stainless steel are favored for their durability and resistance to corrosion, offering an excellent balance between cost-effectiveness and expected service life. These choices extend the lifespan of pressure tanks and ensure operational reliability.

Key Design Parameters: Pressure, Temperature, and Stress Considerations

The design process of a pressure tank is underpinned by a series of critical calculations and considerations. Manufacturers must account for design pressure, maximum permissible working pressure (MAWP), and design temperature to assess the limits within which each tank will operate effectively. Stress analysis and joint effectiveness are also taken into account, ensuring that every tank can safely handle the forces it will be subjected to. A margin for corrosion is included to counter the inevitable degradation over time.

| Material | Corrosion Resistance | Durability under Pressure | Expected Longevity |

|---|---|---|---|

| Steel | Good with protective coatings | Excellent | 8-10 years |

| Stainless Steel | Excellent | Excellent | 15-20 years |

Following these stringent design requirements ensures that pressure tanks can be operated safely and efficiently for their entire service lifespan. Furthermore, the manufacturing process rigorously adheres to industry standards, including steps such as forging, rolling, and meticulous welding, topped off with a post-weld heat treatment to maximize strength and integrity. This results in a product that you can rely on for consistent operation and safety.

Installation and Maintenance: Ensuring Pressure Tank Reliability

When it comes to household components that play a pivotal role in your daily life, your pressure tank is one of the unsung heroes. The installation and maintenance of your pressure tank are critical to its reliability and the longevity of your water system. To keep your system in top working order, understanding the pressure tank installation process and pressure tank uses is crucial. A misstep in installation can lead to issues down the line, and lack of proper pressure tank maintenance can decrease the efficiency of your water system and potentially lead to costly repairs.

Once your pressure tank is correctly installed, consistent upkeep becomes the key to the smooth operation of your water system. This means regularly checking the tank’s air pressure to ensure it matches the recommended settings. It’s suggested to check this every six months to avert operational imbalances. Another critical maintenance task involves inspecting the tank for possible leaks, which can hinder performance. Here, visual inspections combined with periodic checks of the surrounding area for water pooling can help identify issues early on.

Beyond these checks, you should also verify the condition of the valves, switches, and the tank’s structural integrity. Paying attention to any signs of wear or damage can help you to spot any potential issues before they escalate. However, remember that work on pressure tanks often involves dealing with high pressures and potentially complex systems. Should you encounter any issues or if you require guidance concerning pressure tank maintenance, it’s recommended to contact a professional.

- Ensure proper installation to facilitate optimal performance and prevent future issues.

- Conduct biannual checks of the air pressure levels within the tank.

- Regularly inspect for leaks or signs of wear in the tank and its associated components.

- Explore the uses of your pressure tank to apply best practices in maintenance routines.

Your diligence in pressure tank maintenance is not only about avoiding disruptions; it’s also a safety measure. A well-maintained pressure tank contributes to the overall safety of your household. In summary, by making sure of proper pressure tank installation, and staying on top of routine maintenance, you are securing the efficiency, safety, and durability of your water system for years to come.

The Wide Array of Applications for Pressure Tanks

When you consider the vast landscape of modern industry, pressure tanks emerge as unsung heroes. Known for their pressure tank uses, these versatile vessels store and manage pressurized fluids—a vital function across numerous sectors. The pressure tank applications are as varied as they are essential, underscoring the pressure tanks benefits for consistent, reliable operations.

In the realm of residential infrastructure, pressure tanks are integral to well water systems by sustaining an even water supply and managing pressure levels. Their role in maintaining a steadfast water flow cannot be overstated, providing both convenience and a protective measure for plumbing systems. But the utility of pressure tanks extends far beyond the home.

- Oil and Gas Industry: Here, pressure tanks are pivotal in the storage and separation of oil, gas, and water during extraction and processing stages.

- Chemical Processing: The secure containment of reactive and hazardous chemicals is made possible by the robust design of pressure tanks.

- Food and Beverage Production: Pressure tanks facilitate the processing and fermentation processes, ensuring safe, hygienic, and efficient production.

Commercially, pressure tank applications span a variety of systems. HVAC units rely on them for regulating coolant and refrigerant pressures, while irrigation systems in agriculture use pressure tanks to distribute water evenly across fields. Hydraulic systems too leverage the energy management capabilities of pressure tanks for smooth and powerful machinery operation. Indeed, the spectrum of pressure tank uses is broad, including but not limited to:

| Industry | Pressure Tank Function |

|---|---|

| Petrochemical | Pressure regulation for safe material handling |

| Medical | Gas storage for patient care and surgical procedures |

| Aerospace | Control systems for various atmospheric pressures |

| Water Treatment | Backwash and recycling processes |

The capacity of pressure tanks to safely harness the power of compressed fluids is unmatched. They provide both safety and efficiency, safeguarding processes and contributing to superior end products—benefits that underscore the importance of pressure tanks in modern-day engineering and technology. Whether you’re drawing water from a well, operating in a factory, or managing large-scale industrial processes, the reliability of pressure tanks is undeniable.

Your understanding of pressure tank uses can be further enriched by acknowledging their contributions to environmental conservation. With their ability to operate efficiently and reduce energy usage, pressure tanks help in minimizing the ecological footprint of the industries that employ them.

As you navigate the diverse industries that rely on these robust containers, it becomes increasingly clear that the role of pressure tanks is both significant and ubiquitous. It’s a testament to their design and functionality that they’ve found their way into the core operations of sectors striving for precision and reliability.

Conclusion

As we’ve detailed throughout this article, pressure tanks are essential for maintaining the functionality and efficiency of both residential and commercial water systems. By understanding pressure tank technology, you can appreciate the inherent advantages these systems offer—ranging from constant water pressure to the overall reduction of mechanical stress on water pumps. The reduced frequency of pump cycles not only conserves energy but also reduces wear, which can save on costly repairs and extend the life of your water system.

Modern advancements in design and materials have expanded the types of pressure tanks available, leading to innovations that focus on performance enhancements and lowered maintenance demands. With each development, from increased corrosion resistance to better separation of air and water, the notion of pressure tanks explained becomes more than just a discussion about storage—they symbolize a commitment to cutting-edge efficiency and system reliability.

Whether you’re installing a new system or updating an existing one, proper pressure tank sizing, diligent installation, and consistent maintenance are key to ensuring these components serve your water needs effectively for years to come. As a savvy homeowner or business operator, recognizing the critical role these tanks play in your water system management is an informed step towards optimizing your operation’s performance and safeguarding your investment.

FAQ

What are the benefits of pressure tanks?

Pressure tanks offer consistent water pressure, reduce pump wear by minimizing start-stop cycles, ensure water availability during peak demand, and improve the overall reliability and efficiency of water systems.

How do pressure tanks work?

Pressure tanks work by utilizing the compressibility of air to maintain water pressure. As water fills the tank, the air is compressed, creating the pressure needed to supply water whenever a fixture is turned on, without the pump running continuously.

What is the working principle of a pressure tank?

The working principle of a pressure tank is based on the physical properties of water and air. Water cannot be compressed, but air can be, which means as the water volume increases in the tank, the air is compressed, thus building up pressure that can be used to move water through the system.

Can you explain the pressure tank technology and its upgrades?

Pressure tank technology has evolved from simple air-over-water tanks to sophisticated bladder or diaphragm tanks. Upgrades include the separation of water and air to prevent waterlogging, materials that resist corrosion, and designs that ensure more consistent water pressure with reduced maintenance needs.

What types of pressure tanks are available?

There are several types of pressure tanks, including traditional galvanized steel tanks, air-over-water tanks, and modern bladder or diaphragm tanks, each with their own set of benefits for specific applications.

What are the typical applications of pressure tanks?

Pressure tanks are used in residential, commercial, and industrial settings, including well water systems, HVAC systems, irrigation, petrochemical, oil and gas industries, and wherever fluid pressure control is needed.

How do you size a pressure tank for a private water system?

Sizing a pressure tank typically involves a formula based on the flow rate of the pump. For diaphragm or bladder tanks, the capacity should be about four times the pump’s flow rate. For steel tanks, the capacity should be about ten times the flow rate. Specific applications, such as low-yield wells, may require additional consideration and expert consultation.

What role do Variable Frequency Drive (VFD) systems play in pressure tank operation?

VFD systems maintain constant water pressure by adjusting the speed of the pump motor based on water demand. This results in less reliance on large pressure tanks, often only requiring small tanks, while optimizing energy consumption and providing stable water pressure.

What are the key design considerations in manufacturing pressure tanks?

Manufacturers must consider materials that offer durability and corrosion resistance, design parameters like maximum allowable working pressure and temperature, stress considerations, and ensuring the tank’s integrity through calculated safety margins and rigorous production processes.

How important is pressure tank maintenance?

Regular maintenance of pressure tanks is crucial for system efficiency, safety, and the tank’s lifespan. This includes checking air pressure, inspecting for leaks, and ensuring all components are functioning correctly. Proper installation is also essential for optimal performance and safety.

This post contains affiliate links.

[…] How does the WaterWorker Waterworker-HT20B operate? […]